Transitioning from an unsustainable soy agriculture to a sustainable one requires market pressures that favor the latter. But how do you know whether soy is sustainably sourced, without contributing to tropical deforestation, or to climate change? Transparency is the key: without knowing where each bushel of soy comes from it’s impossible to measure impact, or to shift industry practices. Despite its ubiquity, soy is a latecomer to the transparency space. This is a brief overview of the barriers to adoption and how they’re being overcome.

Soy is one of the world’s most important crops, finding its way into animal feed, vegetable oil, even industrial chemicals. It is one of the most intensively grown: worldwide 1 in 10 acres of agricultural land is dedicated to soy. And it’s one of the most impactful: soy is the second biggest driver of deforestation worldwide (after beef) and the second biggest user of pesticides in the US (after corn). There has also been tremendous progress in soy sustainability driven by industry alignment: the 2010 Amazon Soy Moratorium essentially stopped deforestation of that forest for soy farming. And regenerative agriculture techniques can reverse the carbon footprint of soy agriculture by allowing the soil to sequester carbon. But it’s not enough: deforestation has migrated from the Amazon to the Cerrado, the savannah that covers 20% of Brazil. And worldwide production has a long way to go to catch up to regenerative standards.

Supply Chain Transparency: What is it?

Unheard of just ten years ago, supply chain transparency has become the established best practice for high-risk commodities such as cocoa and palm oil, and industries ranging from cosmetics to food and fashion. It represents a holistic approach to managing the end-to-end supply chain including performance and risk. Industries begin the process of transparency in response to risks to operations and reputation, as a way to provide assurance that responsible sourcing and compliance practices are really working, and to align internal staff and outbound sales. No matter the motivation, supply chain transparency consists of four steps:

1. Supply chain mapping

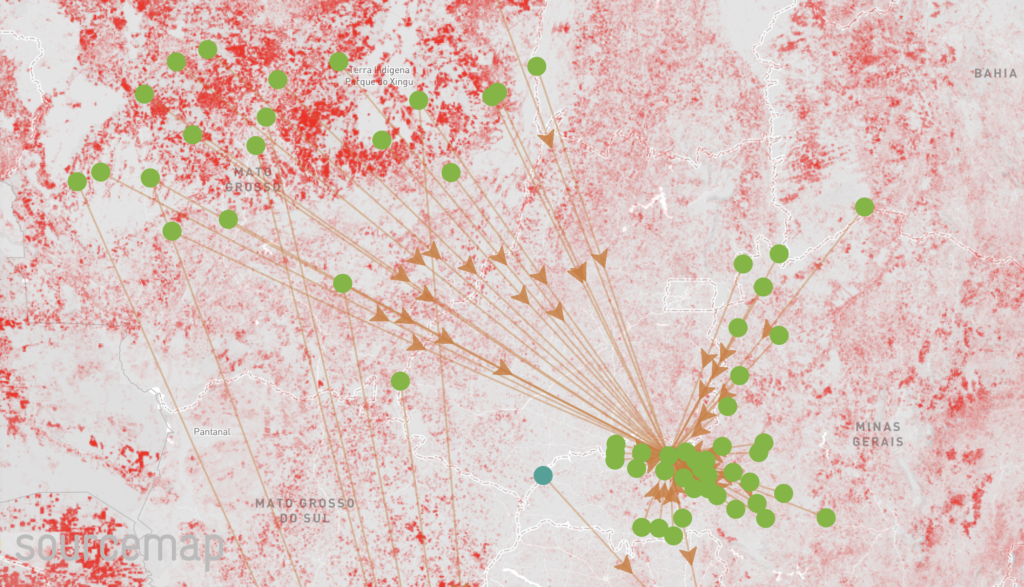

Manufacturers and brands far from the soy farms often lack data on exactly where their soy raw material is being grown. Supply chain mapping uses cascading surveys, market intelligence and trade statistics to provide a detailed map of all soy sourcing regions, preferably down to the individual farms.

2. Continuous improvement

Supply chains are complex, and without focus it’s easy to waste precious resources on interventions that won’t deliver. Fortunately supply chain mapping (step 1) opens up a communication channel to second- and third-tier suppliers so that brands can collect key indicators of social and environmental performance. Combined with innovative data analytics like satellite monitoring for deforestation and built-in calculators for soil carbon sequestration, the supply chain mapping process can become an effective tool for monitoring performance and ensuring continuous improvement towards corporate sustainability targets.

3. Verification

For importers of raw materials, it’s not enough to map the supply chain: a systematic due diligence approach is required to ensure that soy really came from where it was supposed to, and to respond to any customs or compliance questions without requiring a fire drill each time. Verification is best achieved through transactional traceability backed up by pattern detection and spot audits of purchase orders and receipts – all easy to manage through a next-generation supplier relationship management platform.

4. Communication

The ultimate goal of a successful supply chain transparency implementation is to be able to communicate confidently with customers and with consumers about the sustainable source of soy products. This can be managed once steps 1-3 are complete and automated with a supply chain transparency portal that features B2B security protocols.

Supply Chain Transparency: What are the hurdles?

1. Culture

Supply chain transparency is a transformative practice that rewards suppliers that are willing to provide more information on their sourcing practices – so it’s no surprise that there are reluctant participants. When it’s accomplished on an existing supply chain, the process is best motivated by commercial incentives: premiums, co-investment, reduced audits, joint communications. But it’s most easy to implement from the outset: companies evaluating suppliers can include a transparency requirement as part of onboarding, quickly sorting out which suppliers have a mature mapping and sustainability practice in place.

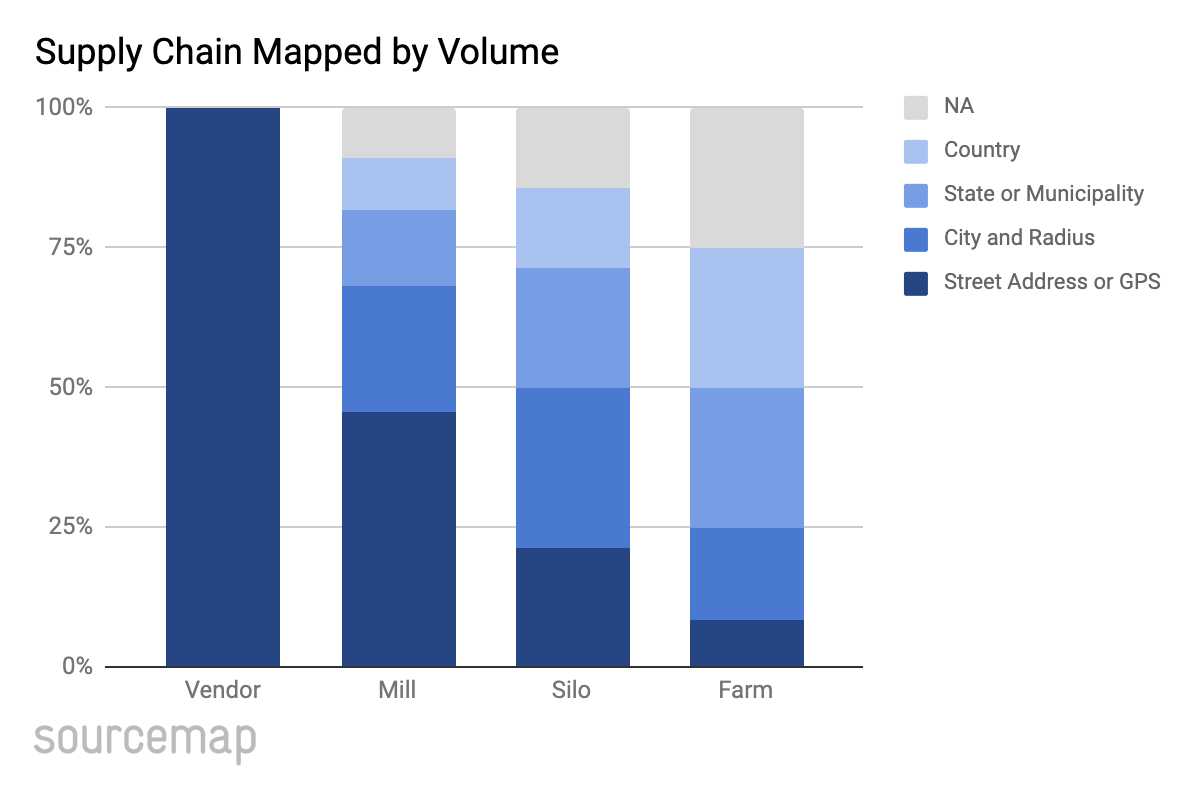

2. Perfection

Supply chains are constantly evolving, and so is transparency. It’s best not to wait for perfection: companies will find that suppliers can provide varying degrees of supply chain visibility, and part of the value of transparency is to quantify that visibility and improve it continuously. The diagram below highlights a common result of a first-wave transparency data collection campaign. While only a fraction of the supply chain can be mapped to origin, it’s much clearer with each campaign which regions and which suppliers need the most help.

3. Unclear Benefit

Supply chain transparency isn’t just an operations best practice: it is a rapid way to uncover risks and inefficiencies. The problem is that without mapping the supply chain, procurement professionals are blind to the potential risks that are waiting to disrupt the indirect soy supply chain. Considering that most supply chain transparency can be achieved in under a quarter thanks to cloud-based mapping, supplier relationship management and traceability technology, that it’s not worth questioning the benefit – the diagnosis is benefit enough.

Next Steps

Supply chain transparency is so ubiquitous that it’s likely your company is already doing it, but not for soy. Cloud-based technologies are making supply chain mapping, supplier relationship management, and traceability just as easy for the indirect supply chain as it has always been for downstream distribution. To learn more about how it’s best performed, talk to your colleagues who have already traced materials like cocoa, palm oil, forestry products, or talk to a supply chain mapping expert. The process is nearly automated and the benefits to your procurement, compliance, security, sustainability, and sales teams will be clear within weeks.

This blog was written and contributed by:

Leonardo Bonanni

Founder and CEO of Sourcemap