This blog was written and contributed by:

Checking your newsfeed and discovering that your organisation has been cited for human rights, environmental, fraud, or other supply chain sourcing violations is an avoidable event.

Given the complexity and lack of visibility in raw material supply chains, sustainability and supply chain teams often rely on auditors, certifiers, consultants and NGOs to collect risk data on their raw materials sourcing. But these approaches can never cover the entirety of sourcing, and can lead to unnecessary risk exposure.

The good news is that technologies have advanced where they can play a critical role in helping supply chain, procurement, sustainability, marketing, risk management, and finance teams improve how they prevent, identify, score, and monitor risks in their supply chains.

The List of Risks Keep Growing

Many companies that source raw materials from environmentally or economically “at-risk” markets are realising that the scope of sourcing risks maybe far greater than their information systems and human resources are designed to detect and manage.

Social responsibility risks include child labour, unsafe working conditions, below living wage income, gender wage inequality, access to credit and other critical inputs, and the use of migrant or undocumented labour.

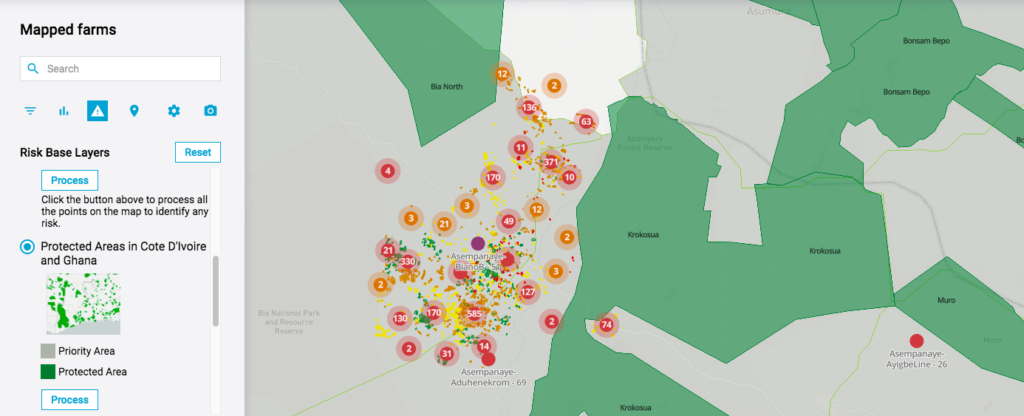

Environmental sustainability risks include deforestation, damage to protected areas and high value conservation areas, GHG emissions and carbon negative practices, product waste, growing or working conditions in extreme temperature, access to clean water, sanitation, biodiversity, poor agronomy and soil nutrition practices.

Operational risks include certification fraud, broken chains of custody, shortfalls or oversupplies of sustainable raw materials, transactions that cannot be audited, low yields from small holder farm suppliers, and hidden costs in multi-tiered supply chains.

Good, but Not Good Enough

Many organisations turn to trusted “boots on the ground”, including auditors, NGOs, consultants, and certification parties to help identify and document potential supply chain sourcing risks.

While these resources can play an important role in sustainable and responsible sourcing, they can be costly to scale, they cannot capture information on changing conditions on a timely basis, they do not provide verification at the transaction level, and they may generate data errors and extra work with data re-entries on spreadsheet and capturing data from disparate systems.

Applying Emerging Technology to Risk Management in Your Supply Chain

Innovation across hardware, software, and communications technologies has been shaping a new generation of solutions that can be used to improve how we manage supply chain sourcing risks.

For example, high resolution geo imaging data from satellites, drones, mobile phones and other image-sensor devices are generating better quality and more timely images and data, which means more precise and useful data is available to detect near real-time conditions impacting landscapes and working conditions, including soil, water, crops, fields, weather patterns and forests.

The challenge for users is how to integrate and turn that data into meaningful and actionable insights for their own supply chains. First, as more technologies leverage open APIs, integrating disparate data sets such as third-party satellite data with supply chain data has become more accessible. Second, with advances in artificial intelligence and data science, users can now extract more value from geo data, including risk detection and automated risk scoring.

We have seen leading brands, including a global apparel brand, leverage these technologies to discover deforestation risks (e.g. exposure to leather suppliers in the Amazon) that they could eliminate so they could verify and communicate with their customers that their products include only 100% sustainably sourced leather.

The use of genetic testing technologies is also beginning to help sourcing teams with validating provenance of select raw materials, including timber. We expect to see the use of both software and sensors to continue to expand the use of genetic diagnostics as a tool for raw material risk management and to mitigate fraud risks.

Finally, we are seeing traceability and verification technology being employed to reduce operational risks, including certification fraud that occurs when certified suppliers attempt to sell raw materials that were sourced from non-sustainable sources. Your sourcing software should have “rails” in place to guard against suppliers that sell volumes that exceed their expected yield or output.

Trace, Verify and Trust

Trust has been a foundation for sustainable and responsible sourcing programmes. However, trust alone has not been sufficient to secure confidence and manage risks in global supply chains. With the application of new technologies, more sourcing teams are able to assure their customers that they are able to trace and verify, which ultimately leads to the highest level of trust.

Protected Area Risk Detection

Roger Brook

Consultant

Sourcemap