The rise of ecommerce has led to significant challenges for consumer goods companies and e-retailers on finding effective and efficient ways to protect fragile products inside last mile delivery parcels, while avoiding excessive packaging.

For 185 years, P&G’s purpose has always been to improve the lives of the world’s consumers, now and for generations to come. We bring this purpose to life by providing products and services of superior quality and value. At the same time, we want to not only be a force for growth, but a force for good, bearing in mind our responsibility to the society and to the environment.

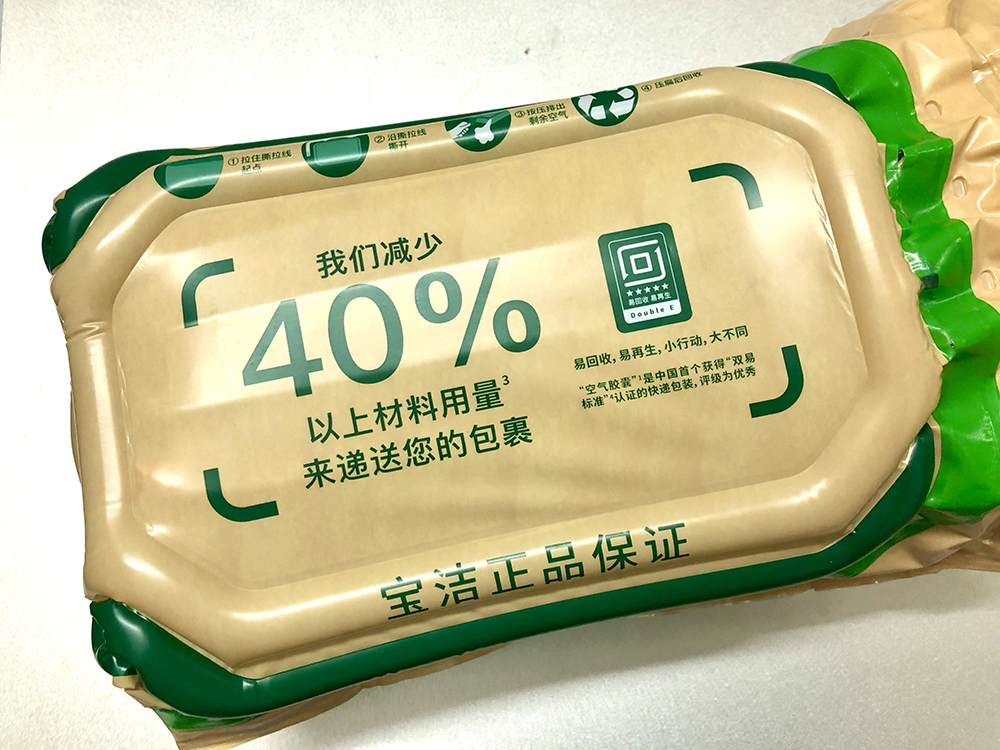

Hence, in 2020, P&G announced our Ambition 2030, which includes a commitment to achieve operational carbon neutrality for the decade. We followed up on this in 2021 with our Net Zero 2040 declaration, with our commitment to achieve Net Zero GHG emissions. Part of the commitments include an objective to achieve using 100% recycled or reusable packaging by 2030. We also set a goal that by 2030, 80% of our E-Com business will not require secondary packaging. The Air Capsule, launched at the 2021 CIIE (China International Import Expo) marks a significant big step towards greener E-Com packaging.

The Air Capsule eCommerce package is developed by P&G to resolve today’s eCommerce packaging challenges in a sustainable way. With more than 12 patents filed globally, the Air Capsule E-Com package has several key benefits vs. traditional parcel that uses corrugated package plus plastic filler or air bags inside:

- Less Material

- Made from 100% single and recyclable material

- Eliminates need for added dunnage, inserts and tape

- Uses >40% less material by weight vs current corrugated parcel package

- More Reliable

- Water resistance to prevent parcel damage

- Highly protective with integrated air cushions to reduce product damage

- Tamper-free opening for content integrity & to prevent product loss.

- More Convenient

- Integrated easy-to-open tear strip, for a scissors-free opening experience

- Auto-deflate feature provides a hassle-free pack disposal after opening

- More Efficient

- Air Capsule requires only 25% of the trucking required to transport the same amount of products vs. those packed in corrugated boxes. It also requires 75% less warehousing space. Thus, this results in operational savings & reduction in CO2 emissions

During the Air Capsule development, P&G innovated a new PE film structure to replace the traditional barrier film (such as EVOH+PE or PA+PE) historically used to provide high gas barrier for extended shelf life. This new PE film uses mono materials needed for 100% recyclability. P&G achieved this by a special proprietary film that meets the requirements for the package structure and air barrier to keep package fully inflated during the last mile delivery timeframe.

On Jun 6th 2022, P&G China announced our “It’s Our Home” sustainability program to guide consumer how to recycle Air Capsule package and promote the green circular economy. P&G also printed “How to Recycle” instruction and “It’s Our Home” mini program 2D barcode on the Air Capsule package to engage and educate consumer how to recycle this package. These are consistent with The Consumer Goods Forum’s Golden Design Rules #2, 6 and 9.

Air Capsule has already secured the TUV Rhineland “Double E” Certification (for Easy to Collect and Easy to Regenerate) reserved for the highest level of Excellence. Air Capsule is first Double E-certified plastic express package in China.

In addition, as part of our ongoing efforts to leverage innovation to drive positive Industry change to protect our planet, Procter & Gamble China joined the GRPG (Green Recycled Plastics Supply Chain Joint Working Group in China) with waste separation, recycling and plastic recycling enterprises. We are currently in a joint venture to carry out the collection & recycling pilot program of air capsule express packaging and other recyclable flexible plastic packages, so we can further develop China-relevant circular economy models.

Remark: the Double E standard is developed by China Green Recycled Plastic Supply Chain Joint Working Group (GRPG). It is the first standard of the evaluation of plastic products’ easy-to-collect & easy-to-regenerate design” . The TUV Rhineland is one of the 3rd party agencies to certify Double E standard.